Notonthehighstreet

Enabling inventory management at Notonthehighstreet

For ‘Partners’ selling products on Notonthehighstreet, managing inventory can take up more time than sourcing stock or even creating handmade items.

Over the course of 2 x 6 week blocks, we explored, tested and provided a solution that would transform how Partners tracked and managed the stock levels of their listings.

I worked as Principal Product Designer, alongside a small team of Product Manager, Researcher (second half of the project), Delivery lead and Front-end & Back-end Engineers.

Designing into a legacy platform

Within a legacy platform that was over 15 years old, Partners had no ability to manage stock levels of their products on NOTHS.

For products that were sold out, they had to mark the product as out of stock. Inevitably, products were over or under sold as a result.

The whole process was hugely time consuming and a poor experience for the partner.

The ‘PIM’ Partner Inventory Management platform. At least 15 years old. A vet would have been kinder.

Just some of the problems we faced

No stock level management - only ‘Low stock’ or ‘Out of stock’.

Stock can’t be tracked, so products frequently get oversold, but also undersold as Partners mark items out of stock as a precaution.

High manual effort. Partners have to edit each product listing individually.

Outdated platform with few engineers able to support. Bugs, bugs bugs…

No data points. None.

Fonts were tiny and colors weren’t accessible…

A platform that nearly destroyed a business

Generative research interviews with partners gave us opportunity areas of focus.

One Partner stuck in mind as their problems with managing stock were heartbreaking.

Overselling nearly cost them their business.

From the interview, I learnt that when making huge sales on Black Friday, this partner oversold what the business was capable of making, but proceeded to fulfil the orders as they didn’t want to let down their customers.

Profit margin was non-existent on oversold products and they had to let half the staff go and very nearly went under.

Stock Management Roadmap

Alongside the Product Manager and Technical Lead, I was integral in defining the roadmap that would deliver incremental value to partners and business alike.

We broke down the work into strategic milestones that would enable faster releases, whilst maintaining the ability to experiment and iterate.

Objective

Add Stock management to PIM to double the amount of products Partners list on NOTHS

Key result - Stock levels

15% of Partners managing stock levels for their products

Discovery

A lot of the effort on the project went into truly understand the problems our users faced. I ensured to make time for in depth research, to truly appreciate the complexities of the many different scaled businesses selling on NOTHS.

Speaking to partners

3 rounds of moderated interviews (approx 18 partners in total)

First round of Generative information gathering.

2nd and 3rd rounds Evaluative, refining questions, testing basic concepts.

1 hour+ interviews over Usertesting.com

Recruitment via internal partner team - mixture of ‘Artisans’, ‘Boutiques’ and ‘Designers’, Small, Medium and Large scale businesses

Stock at a Product level

For the first iteration, a control to set stock tracking on/off and ability to set quantity would enable Partners to manage stock at a basic level and solve their basic needs.

Stock and Variants are assumed to be part of initial product set up and will live at a Product listing level on the ‘General’ tab.

Fast following our competitors

Most of our Partners also sold across multiple platforms - Etsy, Shopify, ebay and Amazon.

I spent time seeking to ‘fast follow’ - gain inspiration and solutions from the existing experiences to use as an early blueprint for concepts and testing.

I performed detailed competitor analysis and created walk through narrated videos to share with the team and to use as reference.

“You can end up staying up all night, monitoring orders, just so you don’t oversell”

By far the biggest problem faced by partners, was the huge amount of manual effort in monitoring and turning off products once stock was used up. Each of these had to be done individually.

One of the biggest companies employed someone solely to control stock manually. This impacted both their and our ability to grow.

Generative findings - Pains and Impacts

No ability to manage stock at all other than in/out

Manually monitoring stock (time, growth)

Overselling (time, growth, customer service)

Underselling (time, growth)

Manual upload of new products (time, growth)

Manual management/editing of existing products (time, growth)

Lack of Variants (front-end improvements, forecasting)

Lack of data feeds/real-time data (monitoring, forecasting)

No integrations with Stock systems (growth, forecasting)

Managing stock levels across multiple platforms (time, growth, forecasting)

Generative findings - Key needs

Basic Stock Management for number of items for sale

Flexibility to Stock Manage or not Stock Manage

Variants

Automatic variant generation

Add their own variants types (eg. Jumper with Alphabet letters on it)

Attach SKU to Variants

Attach images to Variants

Bulk data import/export for new and existing products

Real time stock information

Data feeds of real-time information

APIs for integrations with other platforms for Managing Stock

Add lead time or Preorder for Out of stock products

Assumptions for MVP stock levels

Simple products only

Approx 25% of our products are Simple products (with no complex options or variants). The MVP is intended for use on Simple products only.

Variants not included (yet)

As Stock management is closely related to Variants, designs for Variants should be explored and tested with Partners to ensure initial and future work and fully considered.

However, Variants will not be part of the release.

Mobile in mind

We will not be building Mobile views but will make considerations to easily enable future adaptation to a mobile view.

Pushing back on the proposed MVP

Original thinking for the MVP was that we would keep effort as low as possible and get to release sooner.

However, reviewing some some very early concepts raised concerns for me.

Managing stock at a product listing level would require high effort as the partner would need to change stock manually for each item. This would actually increase work load.

The original ‘General tab’

Negative impacts of Stock at a Product listing level

More manual effort

With stock managed at a Product listing level, Partners would need to go into every single product listing just to gain an overview of stock levels on NOTHS.

Early concept for MVP

Harder to access data

Imagine a high sales period - checking stock on 100 products could take an hour. This is immediately old data! On Black Friday, they’d have to check stock levels constantly.

Increased admin

We want Partners to list more Products. We already have partners who limit their listings to reduce the admin effort. This would create more admin.

It was important to communicate these problems with the team and stakeholders. I used wireflows as a quick method to demonstrate flows and share a better path.

Proposed MVP - Stock at a Product Listing

I used Shopify again as an example of how this might be accomplished. Their existing model was a proven was of managing inventory at single product and bulk levels.

Discusssions with Engineers were also highly profitable. A standalone page and application also meant far fewer dependencies on the existing system, meaning we could after all build faster.

Revised MVP - Stock at an inventory page level

Controls need simplifying

Controls for setting levels are confusing and could be simpler. Partners would be happy with a single field.

Saving at a product level adds friction. Saving could be at a global level.

Testing concepts for fast feedback

The feedback from the initial concepts gave us a lot of ideas but not necessarily a singular clear direction. To help us move in the right direction faster, I proposed research sessions where we would test a lot of concepts, as much to rule out ideas as to implement them.

By now we had a dedicated researcher, giving me much needed time for more exploration.

Many of the designs posed questions rather than solutions. In places I deliberately left elements like filters ambiguous, in order to elicit unprompted needs and to allow our thinking to remain broad.

Across much of the tested, we added, removed and tweaked designs from session to session, based on the feedback, changing designs in as little as half an hour before the next session. This required strong communication between myself and the researcher.

“We wouldn’t use this”

Despite already knowing our solution wasn’t designed with the biggest partners in mind. Getting direct feedback they wouldn’t use it hurt.

But we were working through a roadmap. We had to focus on knowing who we were delivering for on each step and be able to deliver at pace. It was all about the long term benefit.

Key learnings from evaluative testing

Low depends on the product

‘Low’ is different for each product. It might be 900 units for mass produced items or 3 units for something that’s handmade.

Partners know intrinsically what is low, so don’t need alerting.

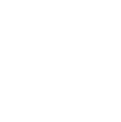

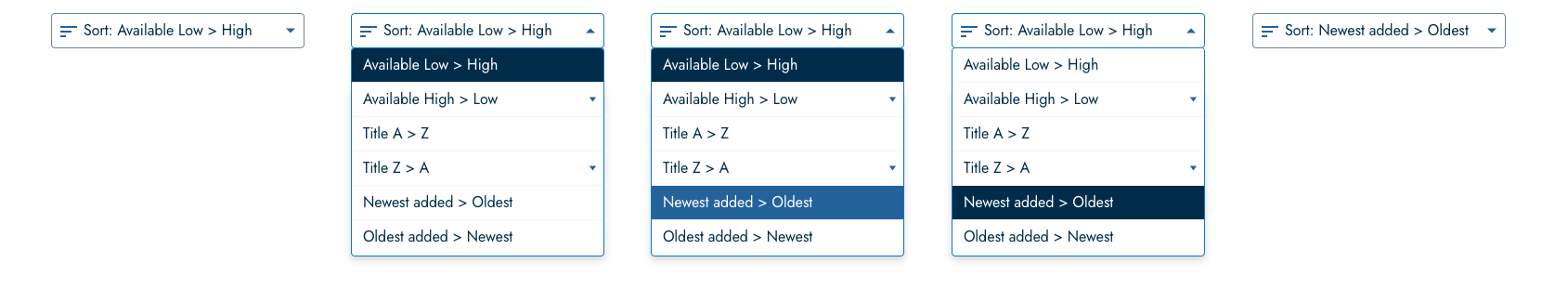

Breadth of filter & sort

A wide range of filters and sort methods are required to accommodate the differing needs of partners. Combinations of multiple filters and sort would enable to refine as necessary.

Partners want more, sooner

Partners, especially the biggest businesses, are still expecting more complex solutions for stock and showed frustration at the limited scale of the MVP approach.

An enhanced but simplified MVP

Feedback from our research sessions enabled us to focus on the key needs of the users and build an MVP that was fast to release and had basic features that we could test, iterate and add to.

Partners were now able to manage stock levels of simple products (no variants or bundles). This was a huge leap for NOTHS.

We gave visual feedback of low stock, as we knew notifications couldn’t be nuanced enough at this stage - we didn’t want users selling a single bespoke product to be bombarded with alerts that their stock was low.

An updated menu would provide some modernity to the existing interface. By keeping this very neutral it would blend in with the existing legacy pages and new areas.

Whilst trying to keep the release to MVP, partners still needed to be ablew to find specific products quickly, as well as get overviews of their stock.

Using existing base patterns from Semantic UI, I work closely with our front end engineers, enhancing filters to create a powerful set of tools that would cover most states of stock.

Our research had given us the key behaviours and needs that would provide partners with the exact sort methods they needed.

Combining filtering with sort gave high level of control to partners as they examined their stock data. Although presented together here, these were added over successive weeks, adding value to the MVP as we released incrementally.

All these were patterns that were added to our growing foundational design system.

Being an accessibility champion at NOTHS, I took care to design patterns and components that were fully accessible as well as elegant.

Despite being completed from start to finish across 3 months, the team managed to go through an exhaustive end to end delivery cycle.

Through discovery and multiple research sessions, we iterated design and evolved the experience into something that would provide immediate value to partners, whilst laying the cornerstones for a massive transformation.

Conclusion

MVP alpha release - 3k+ products stock managed across 100 partners in week 1

Stock levels were released to a small set of partners for testing and feedback purposes.

Even people who told us an MVP wouldn’t be useful added stock levels onto their products and gave positive feedback.

Released to all partners

20%+ initial uptake

Approximately 20% of our partners eagerly added stock levels to their products within the first month.

The high adoption rate reflects the strong value proposition and practicality of the solution.

This enthusiastic response reaffirmed the potential for us to revolutionise inventory management for our partners.